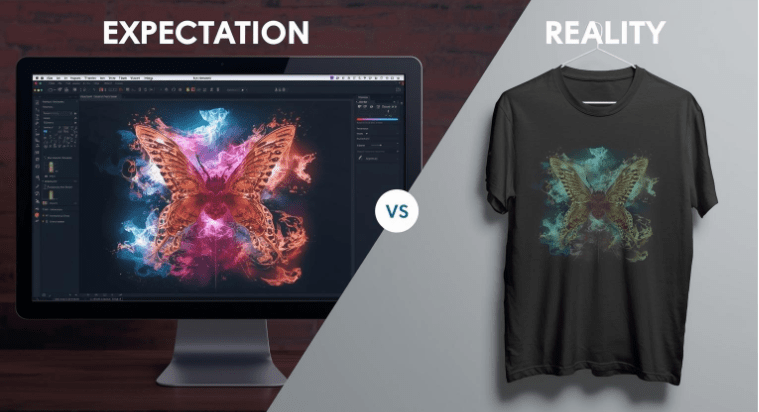

In the hyper competitive world of Print-on-Demand (POD), the promise is limitless customization, but the reality can be brutal. You chase high volume, but you are paralyzed by high returns. Every e-commerce seller, whether running a small shop or managing massive fulfillment, has felt that sinking feeling: an email starting with, “This isn’t what I ordered.” You stare at the complaint: the logo is 0.5 inches too low, or the vibrant green on the screen looks muted on the actual shirt.

That moment defines the “Costliest Lie” in e-commerce: the visual uncertainty baked into every custom order. It’s not the printer’s fault or the customer’s it’s the system’s failure to provide honest visual quality assurance (QA). Traditional POD systems lack the critical feedback loops needed to bridge the gap between a pixelated dream and a tangible product.

This failure doesn’t just annoy a buyer; it destroys your profitability. This guide tackles the brutal reality of custom order returns and shows how a strategic upgrade to Digital Proofing within LPrinter Suite can instantly solidify your brand trust and financial future. We detail the exact operational holes created by ambiguity and illustrate how a unified print platform provides the necessary shield.

The Profit Killers: Understanding POD’s Biggest Pains

The damage caused by inadequate visual assurance extends far beyond the refund button, significantly impacting customer service, production scheduling, and long-term financial modeling.

1. Financial Drain: The True Cost of Wasted Inventory

When a standard product is returned, you restock it. When a custom printed product is returned, it hits the landfill. This causes a severe financial loss because you pay for the item three times:

- Cost 1: Full Cost of Goods Sold (COGS): You’ve paid for the blank shirt, the ink, the labor, and the overhead. This investment is immediately lost.

- Cost 2: Shipping and Logistics: You pay for the outbound shipment (which is rarely recovered) and often cover the return shipping cost.

- Cost 3: Operational Rework: You pay for the labor to process the refund, update inventory records, file claims, and handle the associated customer service hours.

That single return often negatively impacts margin by far more than the initial profit for all unrecoverable wasted inventory. Your entire profitability hangs on just a few percentage points of the return rate. Without firm control over preprint expectations, this loss is simply considered an unavoidable operational expense.

LPrinter Suite Solution: The system is your first line of defense against this cost. It acts as a robust quality assurance system that prevents this expense before the item enters the print queue by demanding visual sign-off. The item is only allowed into production if the customer has approved the exact Digital Proof via the integrated workflow. This pre emptive lockdown minimizes the production of unsellable goods, converting that return loss back into margin.

2. Reputation Risk: Why Returns Destroy Customer Loyalty

Your brand reputation is building one sale at a time and destroyed in one negative review. Customers don’t blame the RGB-to-CMYK color conversion; they blame you for the faded color or the crooked print. The psychological impact of receiving an item that looks drastically different from the website image is immediate and severe.

- The Churn: This leads to a catastrophic high churn rate. You spend marketing dollars (your Cost Per Acquisition) to acquire a customer, only to lose them forever due to a print error. This forces you to spend more on ads, creating a costly, recurring cycle where you constantly chase new customers rather than retain existing ones. When you lack proactive qa, you sacrifice future sales and the vital lifetime value (LTV) of your customer base. A customer who has a perfect first experience is far more likely to forgive minor issues later.

- The Review Impact: A single one-star review citing “inaccurate product representation” can deter dozens of potential future buyers.

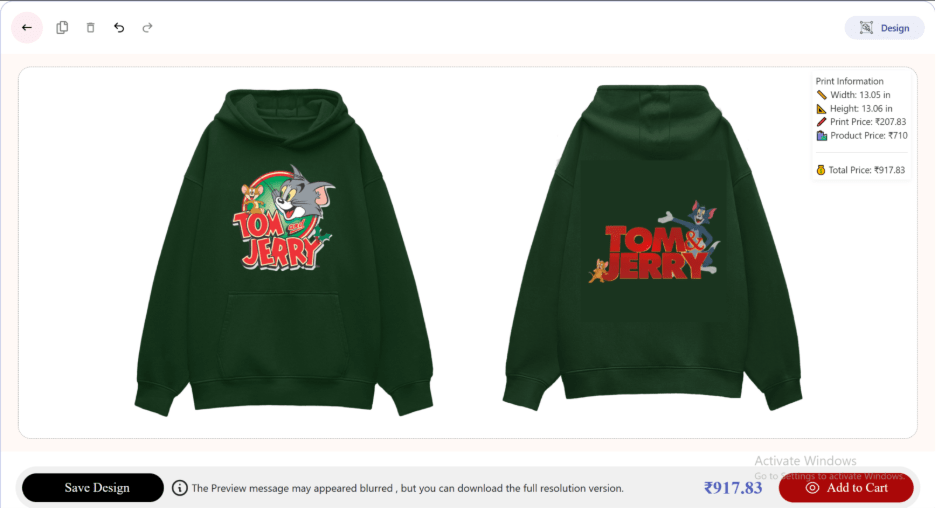

LPrinter Suite Solution: Mockup Previews are integrated directly into your storefront, eliminating the ambiguity that leads to disappointment. We move beyond static images, utilizing realistic rendering engines to simulate how the design appears on the specific garment or product, accounting for color profiles and textures. This first layer of qa sets accurate customer expectations upfront, building customer loyalty and turning buyers into brand advocates who trust your representation.

3. Operational Drag: The Time and Expense of Rework

The chaos of returns imposes a massive cost on your operational efficiency, diverting your customer support team from selling into a full-time dispute resolution department. They spend valuable hours manually comparing customer photos to your original artwork files to manage disputes.

- The Logistical Strain: This results in time spent on necessary reprints and rework, often at the fulfillment provider’s expense. The print shop must halt an active, profitable run to investigate past failures. This disruption slows down the entire facility, increasing lead times for all other orders. Without a standard quality assurance process tied to the order file, the argument becomes subjective, leading to expensive and unnecessary refunds.

- The Resolution Bottleneck: Without concrete, verifiable proof of what was approved, customer service representatives often issue refunds just to preserve the relationship, costing the company money even when the design file was technically correct.

LPrinter Suite Solution: Automated Proofing is the pre-production safety net that provides verifiable evidence. The system automatically generates a proof document that details every specification: exact measurements, CMYK color codes, and the final placement coordinates. This technical document is automatically signed off (digitally or physically by the client in QC) before the job hits the printer.

This creates an unbreakable digital paper trail. If a dispute arises, the seller has legally valid digital proof showing the customer approved the file. This makes customer service instant: “We printed exactly what you approved on the proof of record,” thereby securing your profitability by eliminating subjective design disputes.

4. Quality Challenge: Inconsistency Across Materials

Design files don’t respect reality. The graphics look amazing on a clean white T-shirt, but when you print it on a dark gray polyester hoodie, the colors mute, the texture shifts, and the scale looks wrong. These varied substrates introduce massive risk and lead to inevitable disappointment. Furthermore, when a merchant uses multiple fulfillment partners or devices, the consistency of the output often varies due to differing printer settings and driver configurations.

LPrinter Suite Solution: Standardized QA ensures consistency at scale, directly addressing driver and template variance. The system maintains universal template standards and manages every print device configuration globally from a single pane of glass.

This powerful quality assurance system guarantees that the design validated in the proofing stage is translated perfectly into the print command, maintaining print accuracy and uniformity across different materials, brands, and geographical locations. This level of centralized qa is essential for large B2B clients and retailers who demand absolute uniformity across thousands of shipped units.

LPrinter Suite’s Solution: Guaranteed Quality Assurance Through Data

The goal of LPrinter Suite is to move beyond simple troubleshooting into proactive system optimization. The platform transforms returns from a painful cost into valuable data, fueling a continuous improvement cycle through the very essence of modern, scalable quality assurance.

Data Driven Quality: Turning Returns into Business Intelligence

This is the final, essential step in the quality assurance process. LPrinter Suite tracks not just the volume of returns, but the reason for the return (e.g., “Color mismatch,” “Image too small”) and seamlessly feeds that information back into the system’s core.

- The Loop: This data-driven feedback loop allows the platform to proactively refine its mockup rendering algorithms, template scaling, and color conversion profiles across the entire production chain. If the data shows “Dark Blue on Black T-shirts” is the number one cause of disputes, the system can automatically adjust the preview for all future orders using that combination, effectively fixing a systemic issue globally.

- The Result: The system ensures continuous quality control that lowers future return rates for all clients using the platform, building a perpetually improving, high quality fulfillment service. This is the definition of a mature quality assurance system it learns and self-corrects.

Conclusion: Making Accuracy the New Standard

The sellers who win POD don’t just print faster; they print smarter and with certainty. They treat their print workflow as a mission critical quality assurance process.

The few percentage points of return rate you save by eliminating visual uncertainty will directly translate into thousands of dollars in pure profitability and long-term customer loyalty. Stop subsidizing customer disappointment.

Invest in the LPrinter Suite, the quality assurance system that guarantees print accuracy, builds customer satisfaction, and future proofs your e-commerce brand today.

Leave a comment