The Print-on-Demand (POD) industry operates at a pace unmatched by traditional manufacturing. An order for a single custom t-shirt must transition from a customer’s click to a courier van in a matter of hours, all while ensuring perfect customization and tracking across international borders.

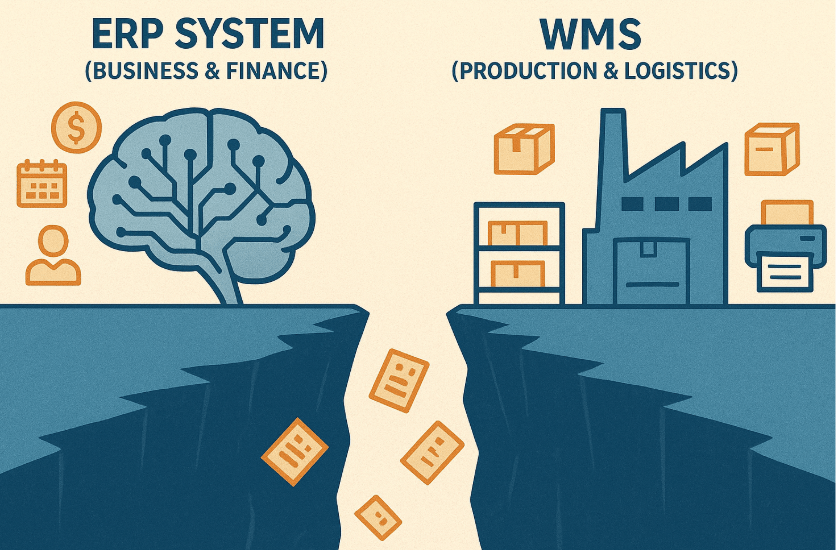

This unique combination of high volume, intense customization, and rapid turnaround demands an entirely new approach to operational technology. Yet, many print fulfillment centers still rely on a Frankenstein model: trying to stitch together a corporate financial tool with a warehouse management application.

While both an ERP system (Enterprise Resource Planning) and a WMS (Warehouse Management System) are essential, attempting to run a modern POD business by forcing two disparate systems to communicate often creates more friction and costs than it saves. This fragmentation is the single biggest bottleneck preventing print providers from reaching a true, profitable scale.

The next generation of POD success won’t belong to companies with the largest IT budgets for integration; it will belong to the companies with the best unified system. To build this future, you must first clearly understand the two core components and why their integration is a mandate, not an option

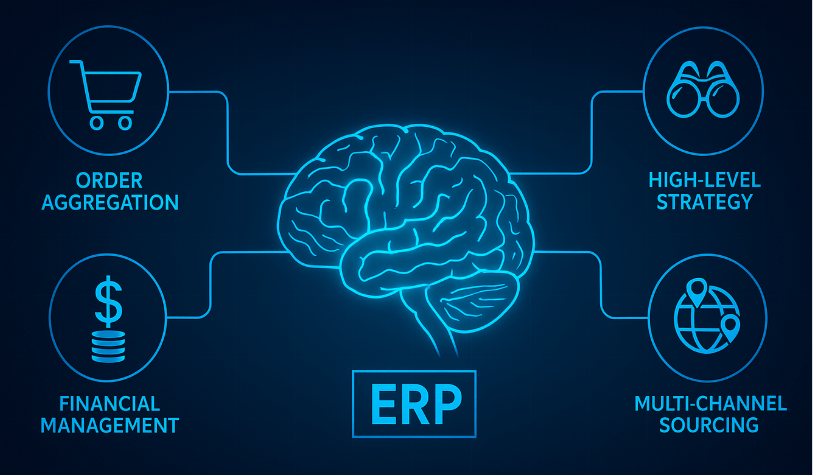

The Brain of the Business: What is an ERP System?

The ERP system is the digital brain of your entire business. It is a centralized database and ERP software application that manages every non-physical, transactional, and financial activity. It provides a holistic, high-level view of your business’s health, focusing on the client, the money, and the overall strategy.

In the POD world, the ERP’s primary job is to serve as the sophisticated bridge between the digital sales world and the physical production floor.

Core Functions of a POD ERP System:

- Multi-Channel Order Aggregation: This is the most crucial function. A modern ERP system must automatically pull, validate, and standardize orders from every source including major platforms like Printify, Gelato, Zazzle, Redbubble, and your own API-connected storefronts. Without this automated, central repository, sales data remain scattered and unmanageable.

- Financial and Client Management: The ERP software handles all transactional logic. This includes calculating pricing across multiple currencies, managing client accounts and contracts, generating invoices, and processing payments. It serves as your single source of truth for all general ledger and profit-and-loss reporting, providing the C-suite with the data needed for strategic decisions.

- Digital Product and SKU Definition: The ERP system defines the digital attributes of every product: the unique SKU identifiers, the product cost, the retail price, and the raw material (blank) that must be consumed to create it. This digital definition is what the WMS will eventually translate into physical action.

- Customer Relationship Management (CRM): It tracks customer history, preferences, and all order statuses. When a customer service agent checks for a delayed shipment, the ERP provides the “why” and the “where.”

In short: The ERP answers the “who, when, what, and how much” of your business. It is focused on clients, money, and high-level strategies.

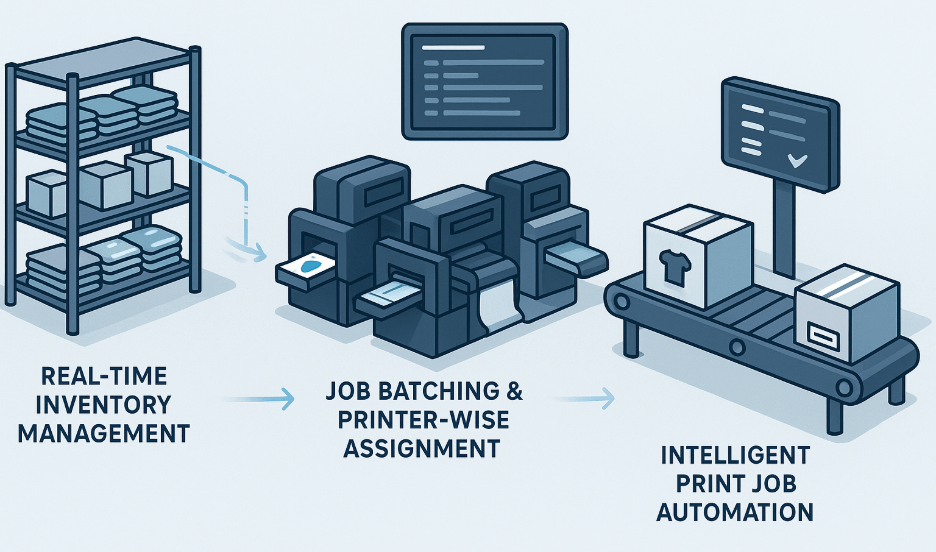

Hands-On Execution: What is a POD WMS?

If the ERP system is the brain, the WMS (Warehouse Management System) is the hands-on muscle of your operation. It deals exclusively with the physical movement, storage, and transformation of materials and products inside your fulfillment center, turning the digital order into a physical object.

In the POD environment, the WMS manages the entire manufacturing and logistics workflow.

Core Functions of a POD WMS:

- Real-Time Inventory Management and Consumption: The WMS is responsible for precision inventory management. It tracks every blank product (t-shirts, mugs, hats) by location, quantity, and variant. Crucially, it tracks consumption when a job is printed, the WMS instantly deducts the raw material from stock. This data is vital to ensure you never oversell a blank product.

- Intelligent Print Job Automation: This is the WMS’s highest-value function in a custom manufacturing environment. It takes the validated orders from the ERP and optimizes them for production efficiency by:

- Job Batching: Grouping similar print jobs (same product type, same machine type) together to minimize machine setup time and maximize throughput.

- Printer-Wise Job Assignment: Dynamically routing the batched jobs to the closest or most efficient printer based on its current load and capability, ensuring optimal print management.

- Quality Control (QC) and Rework Management: The WMS often controls physical scanning and tracking as products move through printing, curing, and packaging stations. It tracks QC checks and, when necessary, manages the rework queue, ensuring the costs associated with misprints are accurately accounted for.

- Final Mile Logistics: Once the product is customized, the WMS manages the final packing, weighing, and integration with shipping carriers. It generates the necessary shipping labels, sends the tracking number, and manages manifests, marking the official end of the physical flow.

In short: The WMS answers the “where, how, and when” of the product lifecycle. It is focused on materials, production, and physical movement on the floor.

The Cost of Fragmentation: The Danger of Data Silos

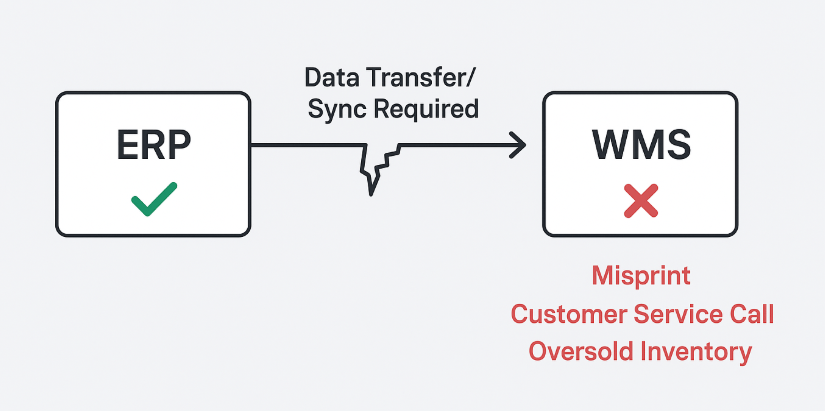

The fundamental problem with operating an independent ERP system and a separate WMS is the gap that exists between them. This gap, known as the data silo, is where errors breed, efficiency dies, and profitability erodes.

1. Financial Loss from Latency and Misprints

If your ERP software is operating on data that is 15 minutes old, it creates catastrophic risks. For example, the ERP might sell 50 units of a rare blank mug based on its last synchronized inventory count. If, in those 15 minutes, the WMS consumed the last 60 units for a large corporate job, the result is an overselling.

This forces a backorder, cancellation, or a costly expedited rush order from the supplier, all of which directly cut into your profit margin. This latency between financial decision-making (ERP) and physical inventory management (WMS) is the single greatest destroyer of efficiency.

2. High Operational and Customer Service Strain

When the two systems are out of sync, the load shifts to your team.

- Customer Service: When a customer calls, the CSR checks the ERP, which shows “In Production.” But the WMS may have already finished printing and is waiting for a carrier pickup. The lack of Real-Time Order Tracking creates unnecessary calls and destroys customer trust.

- Production Planning: Manual intervention is often required to reconcile data discrepancies a print manager wasting time comparing a WMS job manifest to the ERP system order list. This manual time is wasted capacity that could have been used for Job Batching or production oversight.

Fragmented systems turn a high-tech operation into a manual firefighting exercise, eroding staff time and adding complexity that prevents true scaling.

The LPrinter Suite: The Mandate for Integration

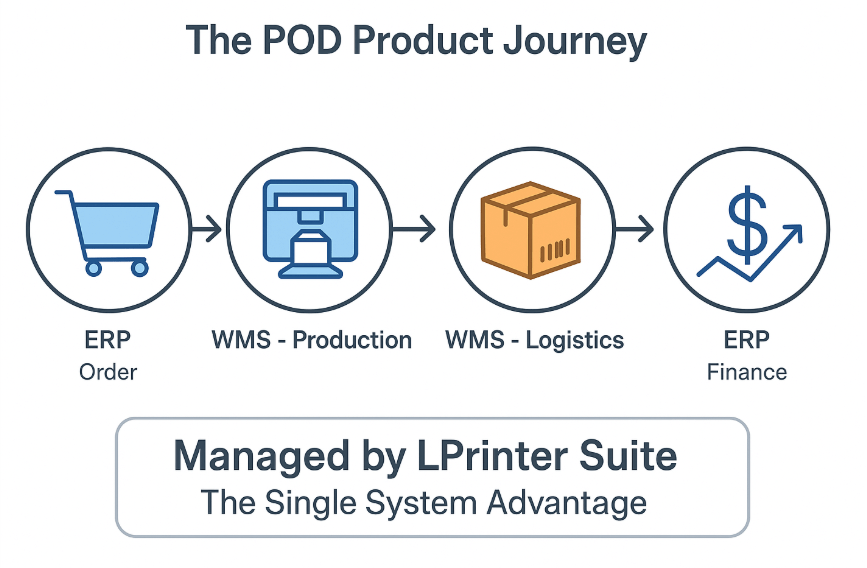

The solution is not better integration; it is no integration. The next generation of ERP system solutions must be built from the ground up as a unified platform that manages both the corporate ledger and the factory floor from a single source of truth.

This is the central value proposition of the LPrinter Suite.

Designed specifically for print providers and fulfillment centers, the LPrinter Suite operates as a single, intelligent engine that eliminates the hand-off risk between systems. It is both a full ERP software solution for invoicing and a powerful WMS for print management.

The Single System Advantage:

- Zero Data Latency: Because Order Management (ERP function) and Print Job Automation (WMS function) operate on the same core database, the moment an order is approved, it is immediately available for Job Batching and Printer-wise Job Assignment.

- Intelligent Inventory: Inventory Management is instant and dynamic. The stock level shown to the sales team (ERP) is the exact, real-time consumed stock level on the floor (WMS). This stability allows you to scale high-volume sales with confidence.

- End-to-End Digital Workflow: The platform seamlessly handles the full process:

- Fetch & Validate (ERP): Orders pulled from all channels.

- Optimize & Assign (WMS): Executes intelligent batching and automatically generates perfect print files (PDF generation).

- Ship & Reconcile (ERP/WMS): Generates labels and instantly updates the client’s order history and the financial ledger.

Built on modern, scalable, and secure technologies like .NET Core, Angular, Azure, and MongoDB, the LPrinter Suite provides the technical backbone needed to sustain the high speeds and demands of modern Print-on-Demand (POD) logistics. It is not a patchwork of tools; it is a specialized, cohesive ecosystem for all your operations.

The future of POD is not about selling generic goods; it’s about selling unique goods at generic speed. This goal is impossible without a unified ERP system and WMS. To compete globally, you must automate the complexity, secure your margins, and eliminate the risk of fragmentation.

Ready to transform your operation from a manual headache into a single, unified engine of profitability?

Leave a comment