The pace of change in logistics isn’t just fast, it’s a revolution. For years, warehouse efficiency was measured by simple pick speed and storage density. But as we look toward 2026, success will be defined by intelligence, autonomy, and the speed of adaptation.

If your inventory strategy still relies on fragile network connections, decentralized print servers, and static processes, you’re not just falling behind; you’re introducing serious operational and financial risk. The next two years will fundamentally reshape how goods are stored, tracked, and shipped.

Business leaders and strategists need to evolve their approach now to capture market share and future proof of their operations. The key to this evolution lies in system orchestration, and logistics, that means starting with the most overlooked piece of the puzzle: print management.

Here are the 5 major inventory trends that will define the operational landscape by 2026 and how a unified solution like LPrinter Suite makes them possible.

1. The Rise of Autonomous Mobile Robotics (AMR): Printing Without the Pit Stops

By 2026, the sight of human workers wasting time walking long distances to a central print station will be rare. The era of the Autonomous Mobile Robot (AMR) has arrived, and it demands mobile, reliable, and instant printing.

- The Challenge: AMRs and mobile picking devices need to instantly print necessary documents for bin labels, replenishment tags, or even cross docking directives at the point of activity. Relying on traditional, bulky, or network-dependent print drivers introduces latency and failure. An AMR can’t wait five minutes for a congested server to spool a job, which kills the productivity gains of automation.

- The Solution: LPrinter Suite’s Direct to Device Architecture. LPrinter Suite bypasses old, fragile Windows print servers, enabling direct IP communication to thousands of printers. This eliminates the central point of failure that can cripple automated workflows. When your AMR device triggers a print job, LPrinter Suite ensures the label fires instantly to the designated mobile or local thermal printer, supporting true “print on demand” at the edge of the warehouse. This architecture guarantees the speed and resilience required for high volume automation.

2. Inventory as a Digital Twin: Centralized Visibility is the New Control

A digital twin is a real-time, virtual replica of your physical warehouse, designed to simulate bottlenecks and predict stock outs. Its intelligence is only as good as the data flowing into it, and every label, invoice, and packing slip is a mission critical data point.

- The Challenge: Disconnected printing leaves a massive data blind spot. You know an order shipped, but can you pinpoint the exact time the shipping label was printed, which operator did it, and the precise, allocated cost? Without this telemetry, your digital twin is incomplete, and your financial models are flawed.

- The Solution: LPrinter Suite’s Advanced Analytics. LPrinter Suite transforms print devices from simple hardware into intelligent IoT nodes. It captures and centralizes metadata for every single print job: the user, the application (WMS/ERP), the time, the printer’s health, and the cost. This detailed report feeds directly into your WMS and ERP systems, providing your digital twin with the real-time print cost and activity data needed for accurate simulation and cost allocation, leading to a 25% reduction in planning cycle time.

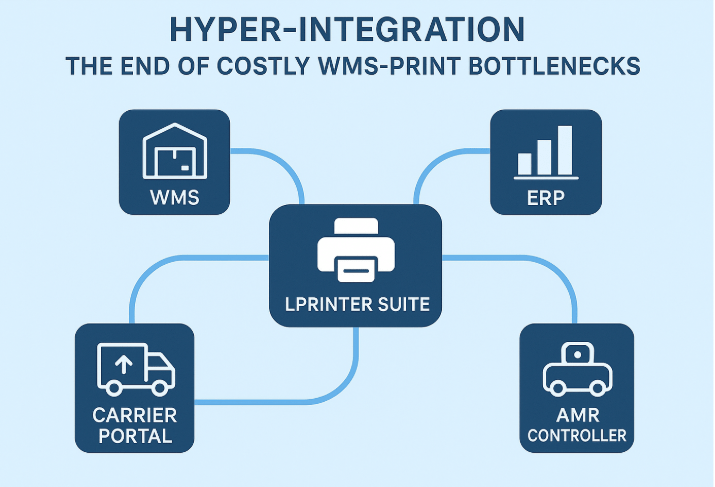

3. Hyper Integration: The End of Costly WMS Print Bottlenecks

The single greatest operational slowdown is the gap between different systems. Your WMS and ERP systems handle inventory logic, but they often struggle when pushing that data to a fragmented, mixed fleet of printers.

- The Challenge: Integration shouldn’t require custom code every time you add a new printer model or open a new depot. The cost and time involved in creating dedicated print drivers and label templates for every WMS implementation (SAP, Oracle, etc.) is prohibitive, leading to nonstandard, error-prone workflows. This driver’s chaos causes major headaches for IT teams.

- The Solution: LPrinter Suite’s Universal Connectivity. LPrinter Suite acts as the standardized print layer across your entire enterprise. It offers universal integration connectors that allow your WMS/ERP to speak one language, regardless of whether the final output device is a Zebra thermal label printer, a Datamax, or a standard HP laser printer. This hyper integration dramatically lowers IT overhead and ensures that mission critical documents are printed with perfect consistency, reducing administrative errors by up to 40%.

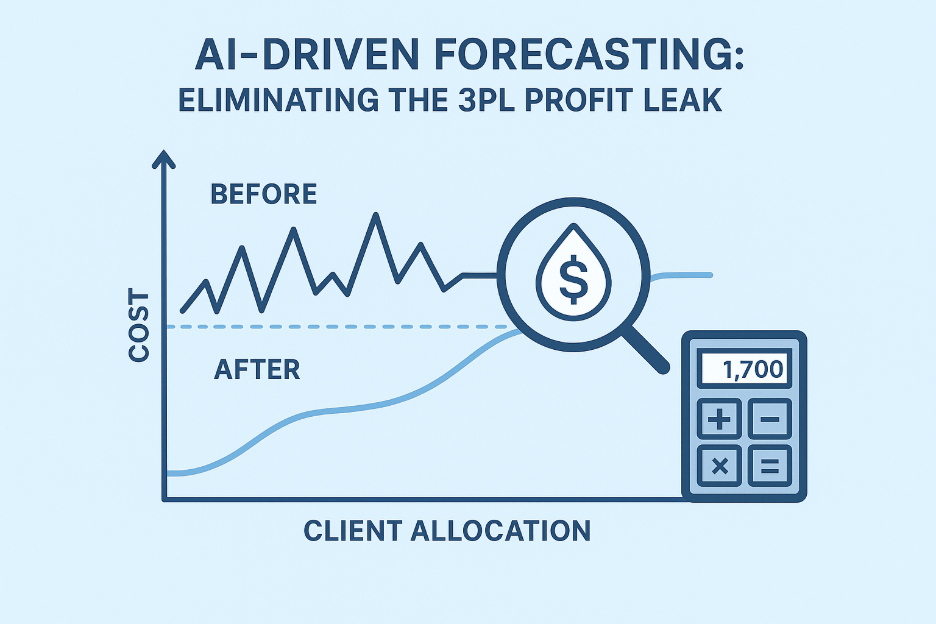

4. AI Driven Forecasting: Eliminating the 3PL Profit Leak

For Third Party Logistics (3PL) providers, AI-driven forecasting is used to optimize stock placement and labor needs. But a major, often hidden profit leak comes from inaccurate client-side billing, especially for consumables and print volume.

- The Challenge: 3PLs must accurately allocate every penny of operational costs including labor, supplies, and equipment usage back to the specific client, project, or department. Manual reporting of print jobs by client code is time intensive and highly prone to error, leading to 3PL subsidizing its own clients’ print costs and compromising profitability.

- The Solution: LPrinter Suite’s Automated Cost Allocation. LPrinter Suite’s reporting isn’t just about volume; it’s about context. It captures print jobs and tags them with WMS/ERP metadata (Client ID, Order ID, Department Code). This allows the suite to automatically generate granular reports that precisely allocate costs for every printed label and document, enabling accurate client chargebacks and transforming a hidden, non-billable cost into auditable, profitable line items. This feature is crucial for 3PL financial transparency and optimized client contracts.

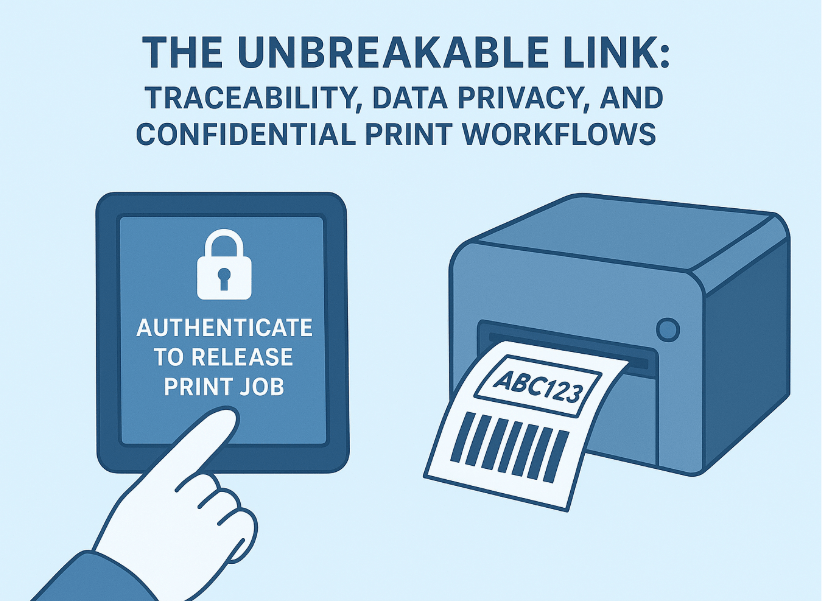

5. The Unbreakable Link: Traceability, Data Privacy, and Confidential Print Workflows

By 2026, complete traceability is mandatory. This means the movement of sensitive data (like customer PII on a shipping label) must be as secure as the physical package itself. Every regulatory body requires absolute accountability for personal data.

- The Challenge: When highly confidential shipping labels are printed and left unclaimed on an open printer tray, they represent a massive data privacy and regulatory compliance risk, particularly concerning Personally Identifiable Information (PII). For regulated industries like Pharma or Food & Beverage, this lack of print accountability breaks the audit trail required for end-to-end traceability and invites hefty fines.

- Solution: LPrinter Suite’s Confidential Print and Auditability. LPrinter Suite enforces confidential print workflows using pull printing technology, requiring the user to authenticate (via badge swipe, mobile app, or terminal) right at the printer before the job is released. This guarantees that sensitive labels and documents only end up in the authorized hands, ensuring data security at the final physical output point. Furthermore, the system keeps an immutable, centralized log of the print transaction, providing the unbreakable audit trail required for compliance and reducing the legal risk associated with handling PII.

Conclusion: Don’t Upgrade Your Warehouse, Upgrade Its Nervous System

The five trends defining the 2026 warehouse all share a common requirement: unprecedented data fluidity and operational resilience.

You can invest in the fastest AMRs, the most complex WMS, and the smartest AI, but if your print infrastructure the nervous system that generates the labels, invoices, and documents that move the goods is outdated, it will become the single most significant point of failure.

LPrinter Suite acts as the crucial middleware, modernizing your print environment to support the autonomous, integrated, and secure warehouse of tomorrow. It’s the platform that takes the print burden away from your mission critical WMS and guarantees that the right document prints instantly, correctly, and securely, every single time.

Ready for future proof of your logistics operation? The time to move beyond fragmented print servers and into a unified, intelligent print management system is now.

Leave a comment