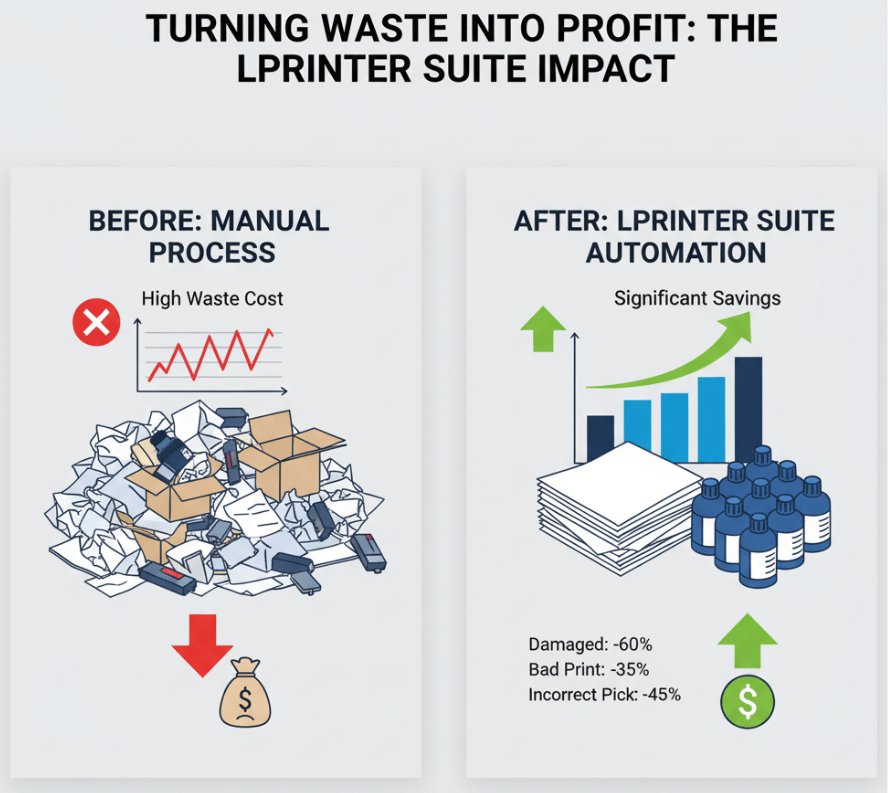

Every print shop owner knows the feeling: you’re striving for efficiency, meticulously managing orders, and delivering quality products. Yet, despite your best efforts, you might be bleeding money in a place you least expect your warehouse. Beyond obvious expenses like rent and utilities, many print providers face significant, often unseen, financial drains due to inefficient warehouse management and unchecked inventory shrinkage. This isn’t just about a few misplaced items; these are the hidden costs of wasted inventory that quietly erode your profitability.

Understanding and addressing these issues is critical for any print business looking to optimize its operations and boost its bottom line. The good news? With the right tools and strategies, these hidden costs can be identified, minimized, and even transformed into newfound profit.

Unmasking the Silent Siphons: Where is Your Inventory Losing Money?

The concept of wasted inventory extends far beyond simply over ordering. In the dynamic world of printing operations, several factors contribute to inventory loss, each with its own ripple effect on your finances:

- Damaged Goods: Whether during receiving, storage, or picking, damaged raw materials or finished products become unusable. This isn’t just the cost of the item; it’s lost opportunity and potential delays in print production.

- Obsolete or Expired Stock: Over time, certain papers, inks, or specialty materials may become outdated, expire, or fall out of client favor. Holding onto this dead stock ties up capital and occupies valuable warehouse space management.

- Production Errors: Misprints, incorrect cuts, or machine malfunctions can render entire batches of materials unusable, leading to significant inventory waste. This directly impacts on your profit margin.

- Misplaced or Lost Items: A lack of robust inventory control means items can disappear into the depths of your warehouse, leading to reorders, delays, and frustrated staff searching endlessly. This inefficiency directly impacts warehouse efficiency.

- Theft: While often overlooked in internal operations, both internal and external theft can contribute to inventory shrinkage, directly impacting your print business profitability.

Each of these points represents not just a lost item, but lost capital, wasted labor, and a direct hit to your profitability. Effective warehouse management systems are essential to prevent this.

From Loss to Leverage: The Power of Data Driven Inventory Management

The first step in turning wasted inventory into profit is gaining visibility. You can’t fix what you can’t see. This is where modern inventory management solutions like LPrinter Suite’s Warehouse Management features come into play.

Imagine having real-time inventory tracking that tells you exactly what you have, where it is, and why it might have been scrapped. This granular data allows you to:

- Pinpoint Problem Areas: Is one specific type of material frequently getting damaged during transport? Is a particular machine consistently causing production errors? Data from a dedicated Scrap Log feature within your warehouse management software can highlight these patterns.

- Optimize Purchasing: With accurate insights into your actual usage and waste rates, you can make smarter purchasing decisions, reduce over ordering, and minimize obsolete stock. This is crucial for efficient supply chain management in printing. You can easily manage supplier details in one place for streamlined procurement.

- Improve Workflow & Training: Identifying the root causes of waste enables targeted training for staff on proper handling, storage, or machine operation. A more efficient print workflow directly translates to better profitability.

- Enhance Accountability: Clear tracking of scrap items allows for better accountability, whether it’s identifying recurring issues with equipment or opportunities for staff training. This boosts overall warehouse efficiency.

LPrinter Suite: Your Partner in Smart Warehouse Management

LPrinter Suite offers comprehensive tools designed to transform your warehouse management from a source of hidden costs into a strategic asset. Our integrated platform provides features that directly combat wasted inventory and boost your print business profitability:

- Detailed Inventory Tracking: Get an accurate, up to the minute view of all your materials and finished goods. Know exactly what’s in stock, where it’s located, and its movement history.

- Scrap Log Feature: Our dedicated Scrap Log feature allows for easy recording of any scrapped item, categorized by reason (damaged, bad print, wrong pick, etc.). This data is invaluable for identifying trends and root causes of inventory loss.

- Production Reporting: Generate comprehensive reports that highlight areas of waste in your print production process, allowing you to make informed decisions for print workflow optimization.

- Automated Alerts: Set up alerts for low stock levels or unusually high scrap rates, allowing you to react proactively rather than retrospectively.

By implementing LPrinter Suite’s Warehouse Management features, print providers can move beyond simply reacting to problems. You can proactively identify and eliminate the hidden costs of wasted inventory, turning potential losses into real, measurable profit. This isn’t just about saving money; it’s about building a more resilient, efficient, and profitable print business for the future.

Leave a comment