As a business owner, you meticulously track every expense, analyze market trends, and optimize your sales strategies. You’re on the lookout for anything that could cut into your hard-earned revenue, from rising material costs to inefficient marketing campaigns. But what if the biggest threat to your profitability isn’t a competitor or a weak quarter? What if it’s a silent, almost invisible thief hiding in plain sight a direct result of poor inventory management?

This thief wasted inventory, also known as inventory shrinkage.

According to a recent study by the National Retail Federation, inventory shrinkage costs businesses billions of dollars annually. This isn’t just about a few misplaced items; it’s a significant financial drain that most businesses, especially those in the printing, manufacturing, or distribution sectors, fail to address effectively. The good news? With the right tools for inventory control, you can not only catch this thief but also turn your losses into real, tangible savings.

The Silent Drain: Understanding the Costs of Wasted Inventory

Inventory shrinkage is the difference between the inventory your accounting records show and the actual physical stock you have on hand. It’s a critical issue that impacts businesses of all sizes, and its causes are far more complex than simple theft. The most common culprits include:

- Damaged Goods: Items that are broken, soiled, or otherwise rendered unsellable.

- Production Errors: Mistakes in printing or manufacturing that result in defective products.

- Clerical & Administrative Errors: Inaccurate data entry, miscounts, or incorrect order fulfillment that compromise effective inventory management.

- Returns: Products that cannot be resold after being returned by a customer.

- Theft: Both external (shoplifting) and internal (employee theft).

The financial impact of these hidden costs extends far beyond the price of the lost item itself. Wasted inventory ties up valuable capital that could be used for other investments, increases storage and handling costs, and can lead to expensive rush orders to replace lost stock. It’s a vicious cycle that quietly erodes your profit margins and indicates a fundamental flaw in your inventory management system. Without proper inventory control, this silent drain becomes an accepted part of the business, a “cost of doing business” that slowly bleeds the company of its profitability.

Stop the Leak: Introducing the LPrinter Suite Scrap Log

At LPrinter Suite, we believe that you can’t manage what you don’t measure. That’s why we developed the LPrinter Suite Scrap Log, a powerful and intuitive feature designed to turn your biggest weakness into your greatest strength. The LPrinter Suite Scrap Log gives you real time visibility into every piece of wasted inventory, helping you identify the root causes of your inventory loss and implement proactive solutions.

Unlike manual methods that rely on scattered spreadsheets or paper logs, the LPrinter Suite Scrap Log is a fully integrated feature of our comprehensive platform. It’s easy to use and provides a central, accurate source of truth for all your scrap inventory, making it an essential tool for modern inventory control.

How the LPrinter Suite Scrap Log Works: Your Data, Your Power

The LPrinter Suite Scrap Log is more than just a reporting tool; it’s a strategic asset for your business. It allows you to log scrap materials and products with a few simple clicks, capturing critical information about each instance of waste. This level of detail is a cornerstone of effective inventory management.

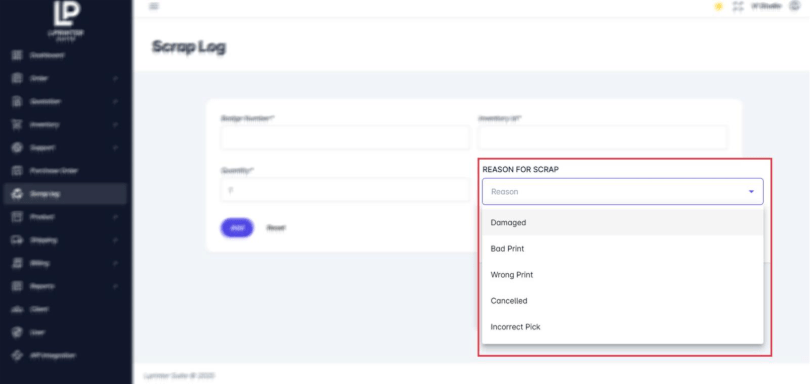

As seen in the provided image, you can quickly categorize the reason for the scrap, choosing from predefined options that provide actionable insights into your manufacturing and inventory management processes:

- Damaged: For items that were broken during handling or storage.

- Bad Print: For misprints due to machine errors, a common issue in manufacturing.

- Wrong Print: For orders that were printed incorrectly, highlighting a breakdown in inventory control or communication.

- Cancelled: For materials that were prepared for a job that was later canceled.

- Incorrect Pick: For items that were mistakenly taken from the inventory, signaling a need for better inventory control procedures.

This detailed categorization allows you to move from simply knowing you have a problem to understanding exactly what is causing it. Is a specific machine consistently producing “Bad Print” jobs in your manufacturing line? Is one employee or team responsible for a high number of “Incorrect Pick” errors, indicating a need for a new inventory management protocol? The LPrinter Suite Scrap Log provides the data you need to answer these questions and take targeted action, leading to better inventory control.

Beyond Reporting: Turning Data into Dollars

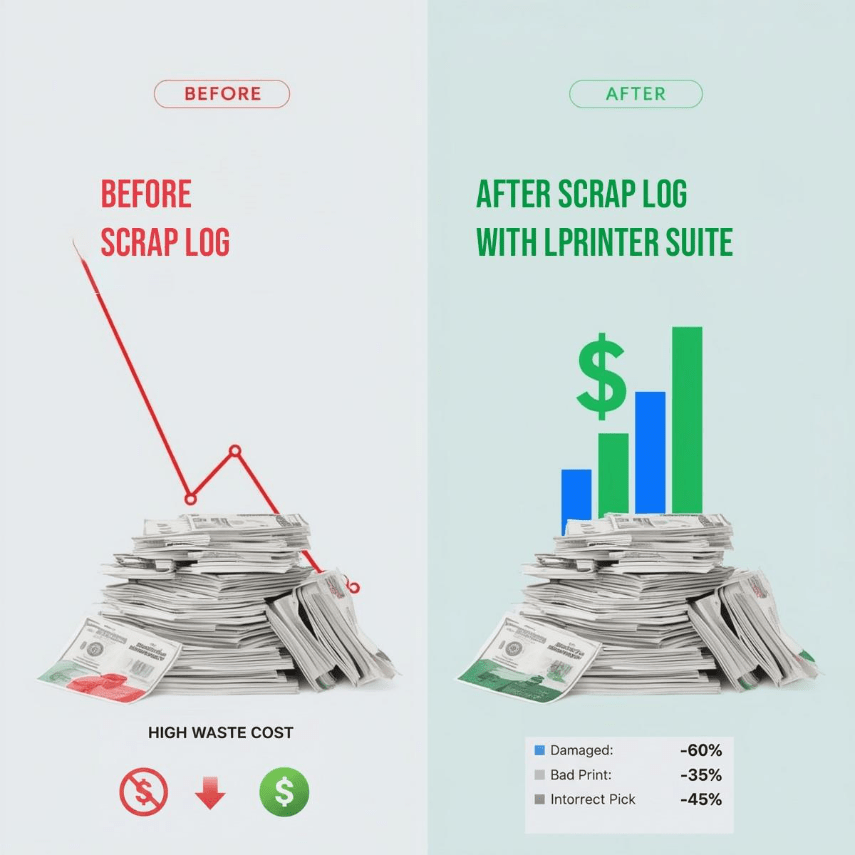

The real power of the LPrinter Suite Scrap Log isn’t just in logging waste it’s in the actionable insights you gain. By consistently tracking scrap inventory, you can refine your inventory management and manufacturing processes to achieve genuine cost savings.

1. Identify Trends and Inefficiencies: Over time, the data collected in the LPrinter Suite Scrap Log paints a clear picture of your operational inefficiencies. You can see which scrap categories are costing you the most, pinpoint specific problem areas in your workflow, and even track the performance of different team members or machines. This detailed view allows for truly data driven decision making in your inventory management.

2. Optimize Your Production Process: Once you know the primary reasons for waste, you can implement targeted solutions to improve your manufacturing process. For example, if “Bad Print” is your top issue, you might invest in machine maintenance or calibration training for your staff. If “Incorrect Pick” is the problem, you could restructure your inventory layout or implement a better barcode scanning system to enhance your inventory control. These strategic adjustments save you money and improve overall operational efficiency.

3. Improve Your Bottom Line: By reducing wasted inventory, you directly impact your profitability. Every dollar saved on materials, labor, and time goes straight back into your business. For a business with an annual inventory turnover of $2 million and a 5% waste rate (a common figure), reducing that waste by just 1% could result in a significant annual saving of $20,000. The LPrinter Suite Scrap Log makes this level of optimization not just possible, but easy, for any business owner.

Get Started Today and Reclaim Your Profit

Don’t let wasted inventory continue to steal from your business. The LPrinter Suite Scrap Log provides the transparency and inventory control you need to identify hidden costs and optimize your operations for maximum profitability. Visit lprintcloud.com today to learn more about how our full suite of tools can help your business thrive and improve its overall business productivity.

Leave a comment